|

| Home |

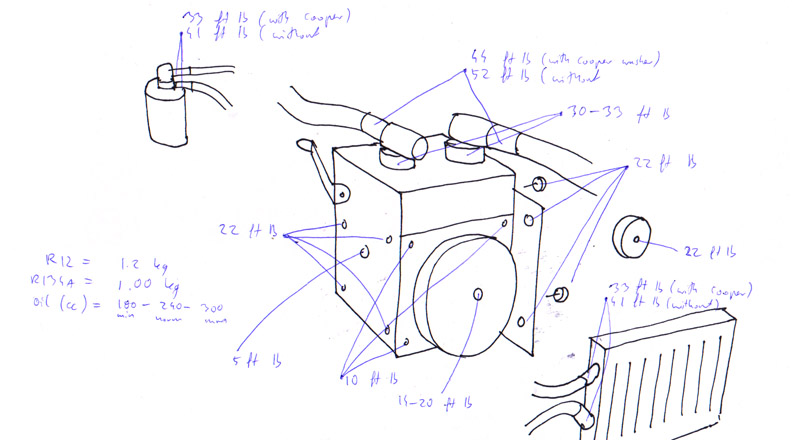

Mercedes AC - York compressor torque specs

The compressor will need service valves - quality ones are not exactly easy to come by. The silver-looking ones are good - but do NOT get the ones that have yellowish plating that you run into easily when searching for those online - they are terrible and will break when you try to tighten them down to the recommended specs. The valves come in a variety of sizes and layouts so be sure to get the correct ones - don't ask me how I know this... You will need to find a clutch that matches with your water pump pulley. This is more difficult then one would anticipat because those come in a variety of circumferences, distance of v-belt grove from the compressor plate and the v-belt thickness itself. Even simple thing like if the clutch mechanism is inside the pulley or not makes a difference potentially causing difficulty with clearing your cooling fan - this M110 engine is tight! Moreover, you don't want clutch that's too small in diameter as this will strain the engine even more than this powerful compressor already is doing. Have a look at the pic below. The clutch on the left had its v-belt grove too far from the compressor plate. The middle clutch is too small in diameter AND those few MM of extra height in clutch mechanism caused the fan clearance issues. The one on the right was perfect but the bottom v-belt grove had to be cut off to clear engine parts:

Beside the compressor, you will most likely also need to buy a new dryer unit and possibly replace the hoses and the expansion valve. I took my chances and left hoses and expansion valve as it was knowing that the hoses will let the R134r escape slowly because of particle size difference. Assuming that your fan and switches are working (thus switching the AC on), you should have no problems rebuilding your AC. What might be hard to find is proper torque specs and here is where this handy cheat-sheet comes in. The torques are specific for York compressor attached to Mercedes engine but i suspect many others will have similar. York compressor torque specs for Mercedes engine: Oil (in CC) -PAG for A135r and Mineral for r12: 180 (min) - 240 (normal) - 300 (max). Hope it was helpful!

|

| copyright 2019 by Patryk Rebisz |