|

| Home |

Solex 4a1 carb - what can go wrong?

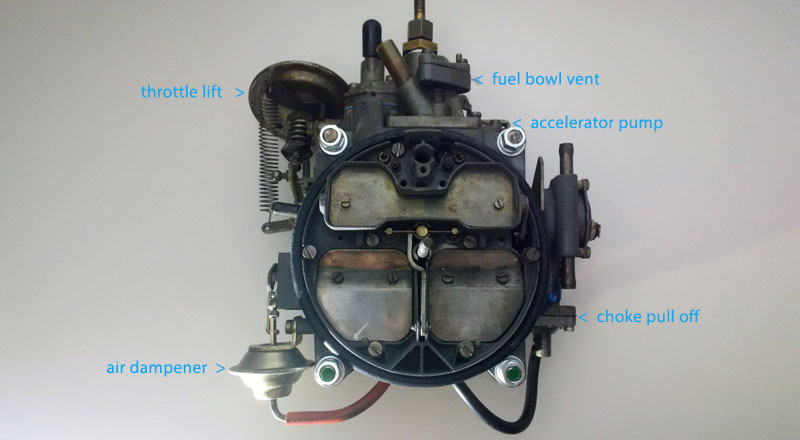

Solex 4a1 is a 4 barrel carburetor. The two smaller barrels feed the engine through most of the driving range, the larger barrels give the engine extra boost when needed. The carb has gotten a bad rap partially deserved and partially due to people's inexperience setting it. The main complain is the warpage of the air horn (top part of the carb that holds the choke and the air flaps for the secondaries). The metal this part is made from is soft and prone to over-tightening. When it warps it can impede smooth opening of the choke or the secondaries air flap. If your carb is warped - there is hope, but if the shafts bind, the repair is way too complex for an average user. When the carb warps, it develops vacuum leaks that can't be easily found by the traditional method of spraying carb cleaner (or other flammable substance) around the gasket edges. Simple and INEFFECTIVE method to fix this condition is to tighten all the screws in effect warping the carb even more. The vacuum leaks are internal exaggerated by the complex layout of the channels feeding the idle circuit forcing the fuel/air mixture to pass through no less than 2 gaskets. The only solution here is to open the carb and use a thicker gasket - that you will have to manufacture as the one in rebuild kit comes with standard thin gasket - in hopes that compressing the thicker gasket material will seal the air leaks. The carb relays on 4 or 5 (depending on model) rubber diaphragms that if leaking due to age can impact its workings. The accelerator pump, air dampener, throttle lift, choke pull off and fuel bowl vent (this sometimes is sealed off in early models and in later an electric switch is introduced instead). Accelerator pump and choke pull off diaphragms come in the rebuilt kits but the other two (or 3) don't. Leak in throttle lift will force you to disable its useful feature of lifting the throttle when vacuum drops due to engine's work (when you turn on AC or when you abruptly close the throttle). Leak in the air dampener will screw up workings of the vacuum controlled secondaries forcing you to permanently disable those killing your drivabilty when the engine's power is needed. You can check those diaphragms by connecting a vacuum pump to each nozzle to see if the part holds vacuum.

Assuming that the gaskets are sealing and the diaphrams are holding vacuum, you now have to deal with setting the carbs as over the years the carb "experts" have probably touched every screw that can be touched. The screws at the bottom of larger vacuum secondaries are meant to be set at the factory with specialty equipment - too bad for the casual user. If the screws were messed with (as they most certainly have) - start with 1/4 screw out. TN choke screws also were meant to be set at the factory and personally I block off the TN choke relaying on traditional choke and fast idle screw. The idle screws should be around 1-7/8 or 2 screws out. Choke pull off vacuum nipple should pull the choke open by 1.5 to 3mm (depending on the version) - this can be regulated by the crew in the choke vacuum housing. The screw holding the spring tension of the air valve of the secondaries should hold the air flap closed. This is hard to get right. The manual calls for a home-build weight of very specific mass but in my experience it doesn't serve well setting the spring tension. You simply must drive with your air cleaner off and preferable RPM installed and listen to when it kicks in. The air flap should open at around 3000 + RPM while pulling hard. |

| copyright 2019 by Patryk Rebisz |